Few Cycle Laser Laboratory

Lasers are quickly becoming the most important technology humanity is developing. With lasers we aim to understand the fundamentals of the universe by creating environments only seen in the most extreme environments, all within the safety of Earth.

In my lab group we aim to create some of the shortest pulse lasers in the world. In order to create more powerful lasers we shorten how long the lasers pulse is. In our case we make the pulse about ~6.7 femtoseconds (10^-15 seconds) or 0.0000000000000067 seconds. This means that a smaller energy pulse is much more powerful than if we had the same energy with a pulse of a larger duration.

UCXS (Ultra Compact X-Ray Spectrometer)

Based off a design from the research article “Ultra-compact x-ray spectrometer for high-repetition-rate laser–plasma experiments”, this device aims to help understand the x-rays produced by laser-matter interactions. We measure the X-ray energies by using a series of Aluminum filters with varying thicknesses to determine what is being produced. The after the x-rays are filtered, they hit an Image Plate, which is later scanned and anylised to provide a profile of the x rays produced.

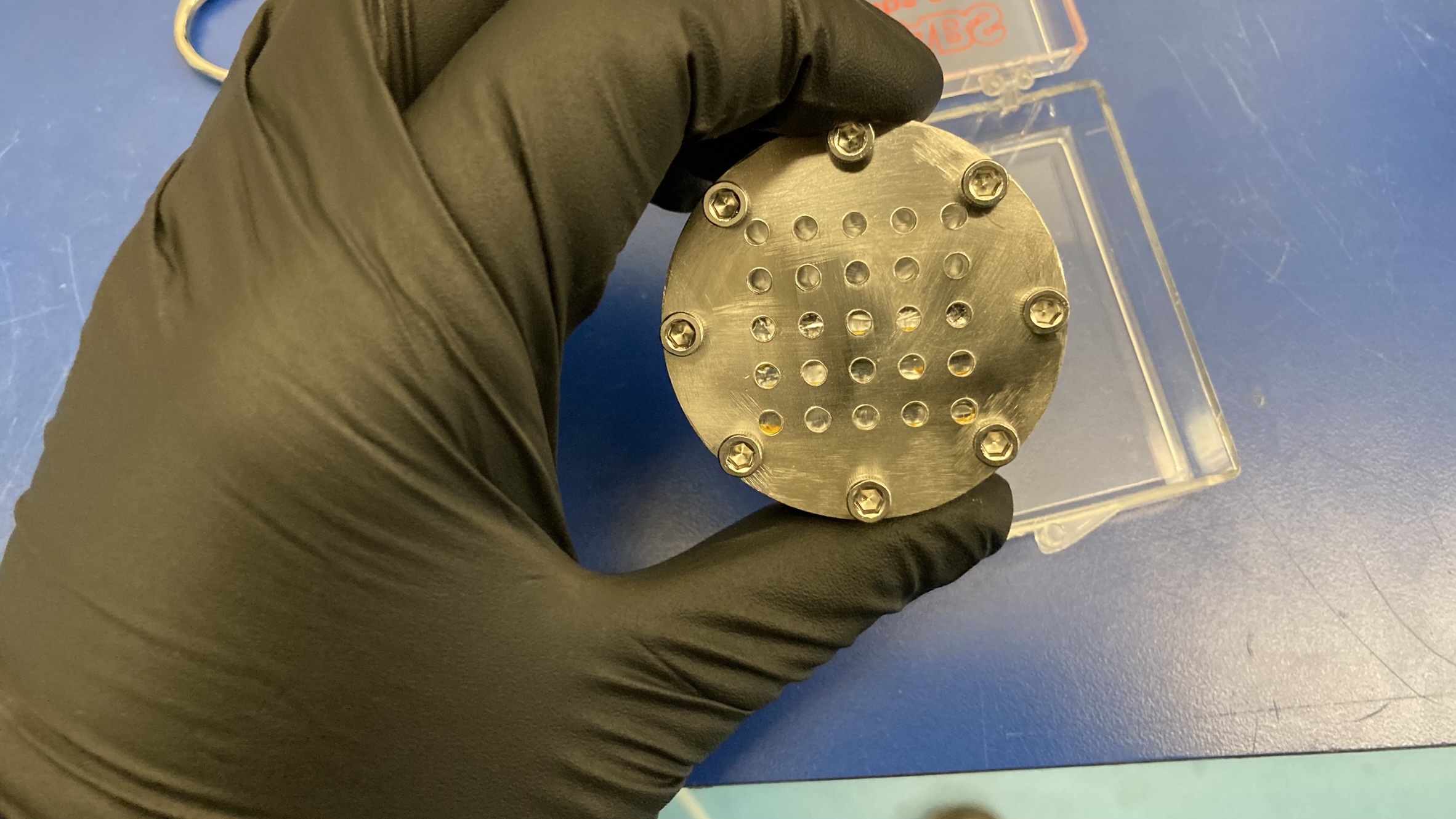

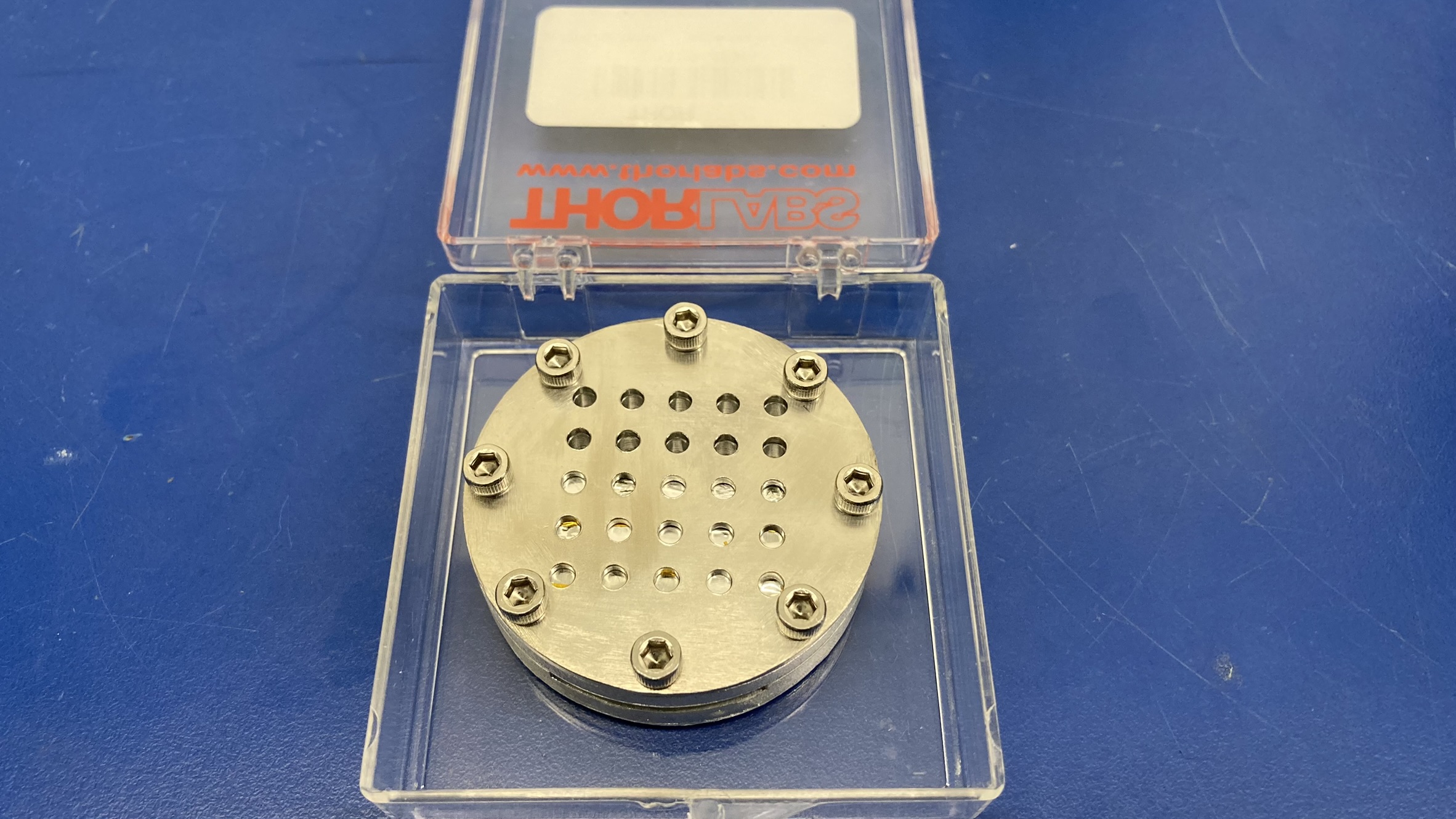

UCXS Electron Deflector

Because an image plate is used to measure the x-ray emissions, special consideration must be given for other particles released during the laser matter interaction. The main one of concern is high energy electrons. These will be much more apparent on the image plate than the x-ray emissions and easily blot them out. To prevent this from happening we designed a magnetic field confined by a ferrous yoke to divert the high energy electrons out of the path of the UCXS.

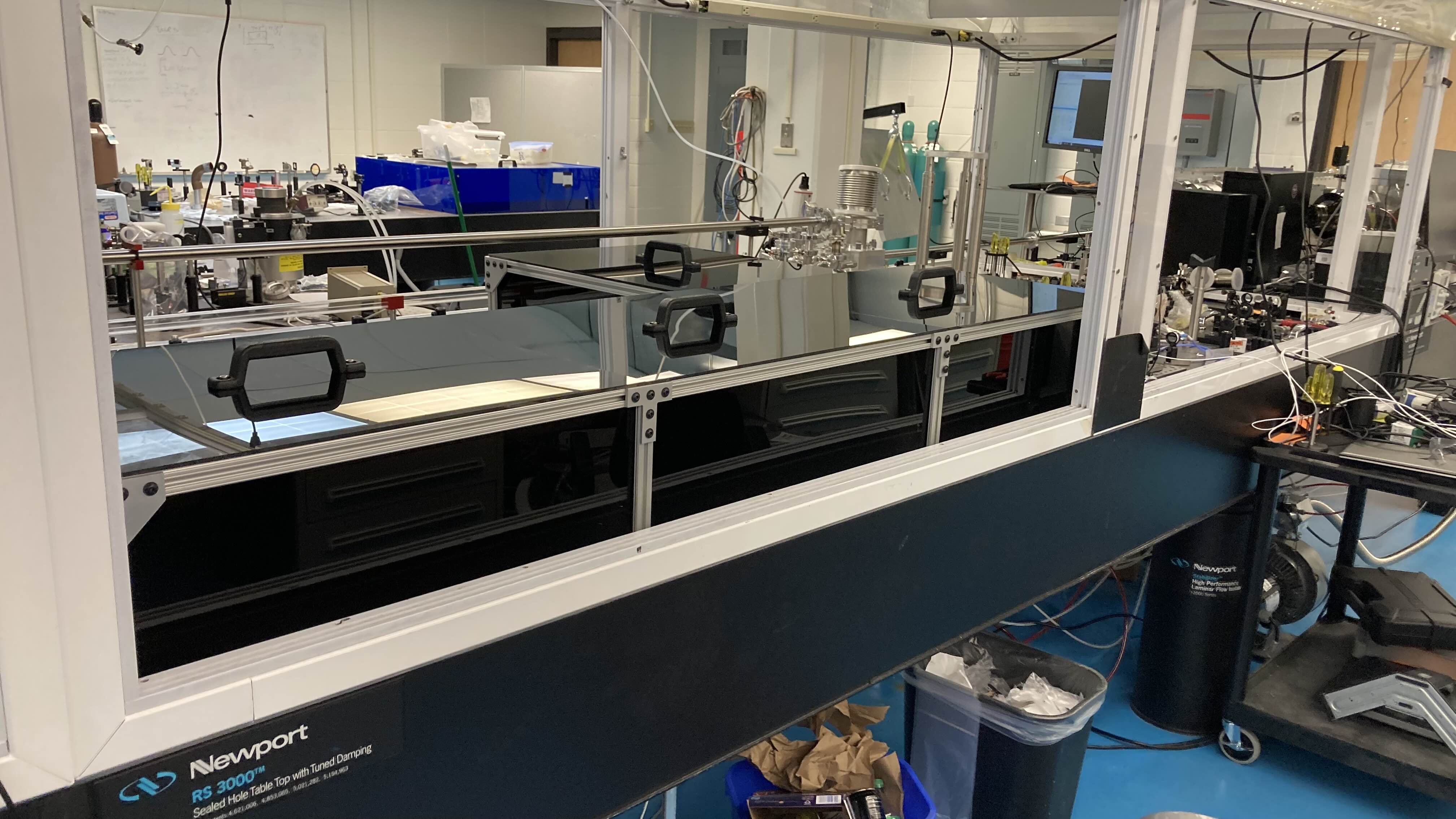

Oscillator and First Stage Enclosures

In order to have a stable laser, it need to start in a stable environment. The project was an replacement to the previous enclosures in order to have proper isolation from unstable air currents present within the lab. Made from extruded aluminum and black acrylic, this enclosure prevents unwanted air currents from disrupting the laser oscillator.

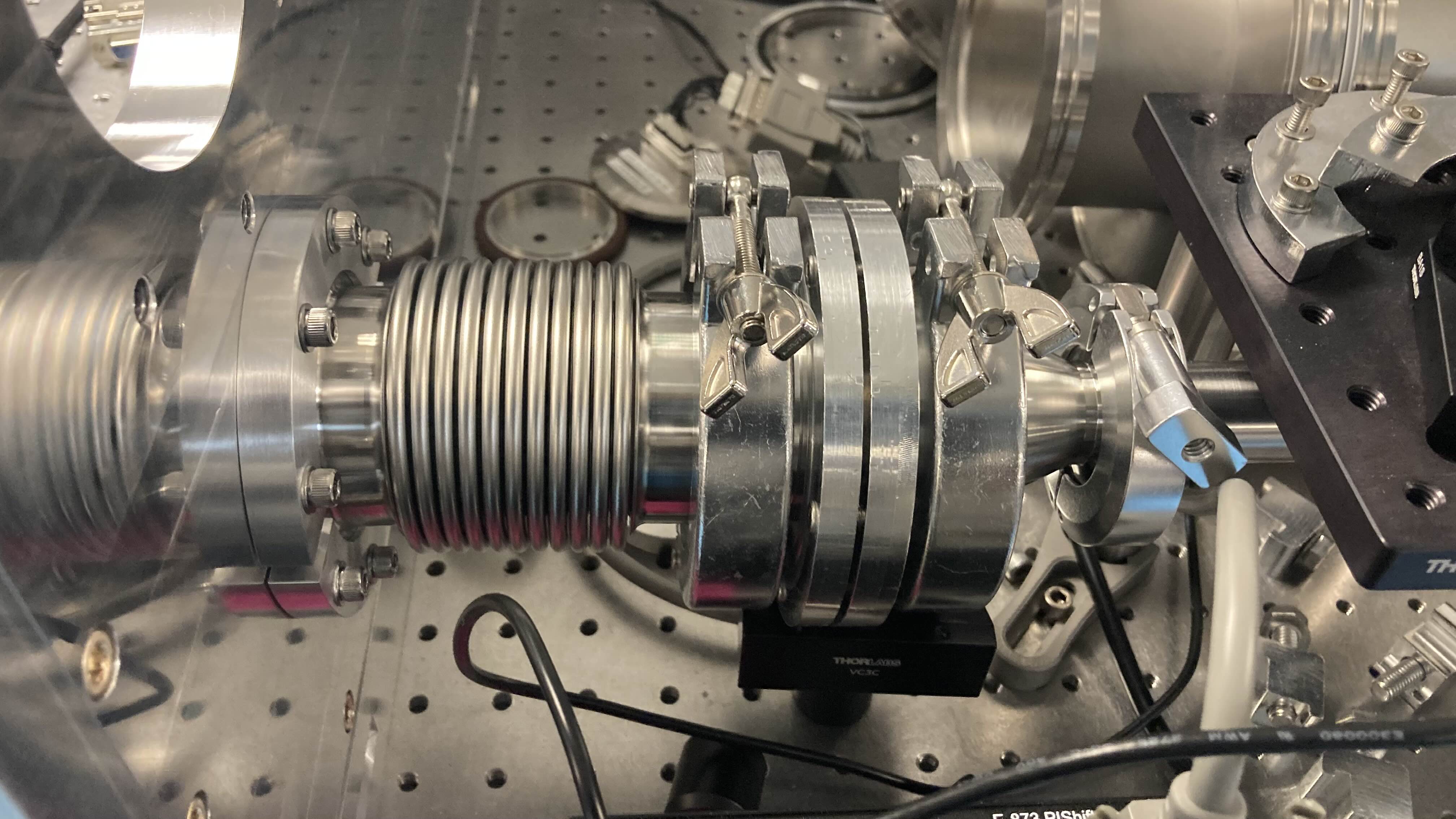

Saphire Window Holder

A new technology on this laser line is its use of a 4-meter hollow core fiber optic. This fiber optic is then filled with helium gas to broaden the spectrum of the laser pulse. The beam must pass through the fiber optic then into vacuum with minimal distortion. A .5mm thick sapphire window provides the barrier between the ~2 bar of helium to high vacuum.

Electron Dispersion Spectrometer

When lasers interact with matter the laser has so much energy it turns the matter into plasma, and tears the electrons off the atoms of the target. So knowing how dense the electron cloud is and how they are distributed within the cloud can be useful data. This design uses a 5 inch ID aluminum tube milled so only 120 degrees of the ID is being used. This allows for an image plate to be used to measure the dispersion of the laser-matter interaction.

Electron Spectrometer

When energized electrons are produced, it is important to know how much energy they possess, as this can be crucial to understanding what is happening when the laser strikes the target. Electrons of different energies have different speeds. This fact along with the fact that electrons are manipulated by magnetic fields in a circular fashion, means we can measure the speed of the electrons and with that the energy of them. This is done with two magnetics in a permeable steel yoke, that direct the electrons up into an image plate to be measured.

Aggies Offroad Racing And Development

Aggie’s Offroad Racing & Development is a multi-disciplinary club revolving around off-road motor sports and recreation. Members gain access to hands-on workshops and appreciation events as well as an inside look at Colorado State University's senior design program. In Baja SAE, engineering students are tasked with designing and building a single-seat, all-terrain sporting vehicle that is to be a prototype for a reliable, maintainable, ergonomic, and economic production vehicle that serves a recreational user market. The students must function as a team to design, engineer, build, test, promote, and compete with a vehicle within the limits of Baja SAE rules.

Website Lead

In March I took over management of the Aggies Offroad website. In this role I have worked to modernize and maintain the website and its information. With organizations websites are important to provide a permanent place for information, my role maintaining the site is crucial to providing accurate information for those curious about our organization.

The website can be found here: https://www.engr.colostate.edu/organizations/aord/

Manufacturing Logistics Lead

In the Fall of 2024 I was elected into the position of Manufacturing Logistics Lead, with this position I have worked to ensure that the buggy is ready for our 2025 competition. This has included starting an inventory of our workspace, so we know what we have and what we need to get. I have also implemented traveler packets for the parts we manufacture, as well as plans to create a standardized part number system for clear communications between team members.

Clock Project

This was the first project completed in Mech 200B The clock project was the culmination of two main manufacturing processes, milling and turning. The main intention of this project was to introduce people to the concepts that they may run into during future courses and careers. It is composed of an aluminum base, a brass pencil holder, a steel pen holder, and an acrylic clock face. These components all had tolerances applied to them, many of which were +- .005, and completed on a manual machine.

CNC Coaster

The CNC Coster was created on a HAAS TM1P 3 axis vertical mill. This coaster was made as the part for the HAAS Basic Mill operator exam. From this exam I received my official certification, as well as validated my skills with using a CNC vertical mill. While there were some concepts were lacking from the exam, I refined them with the laser projects mentioned above.

Screwdrivers

This project aimed to introduce students to concepts such as CNC Turning, Drop Forging, and Heat Treatment. With the addition of injection molding with the second screwdriver. Each process of the project built upon the processes before, helping students to understand how manufacturing process work in the real world. From this project I got more experience with different types of heat treatment which I plan to apply to other projects moving forward.